Stropping leather with paste

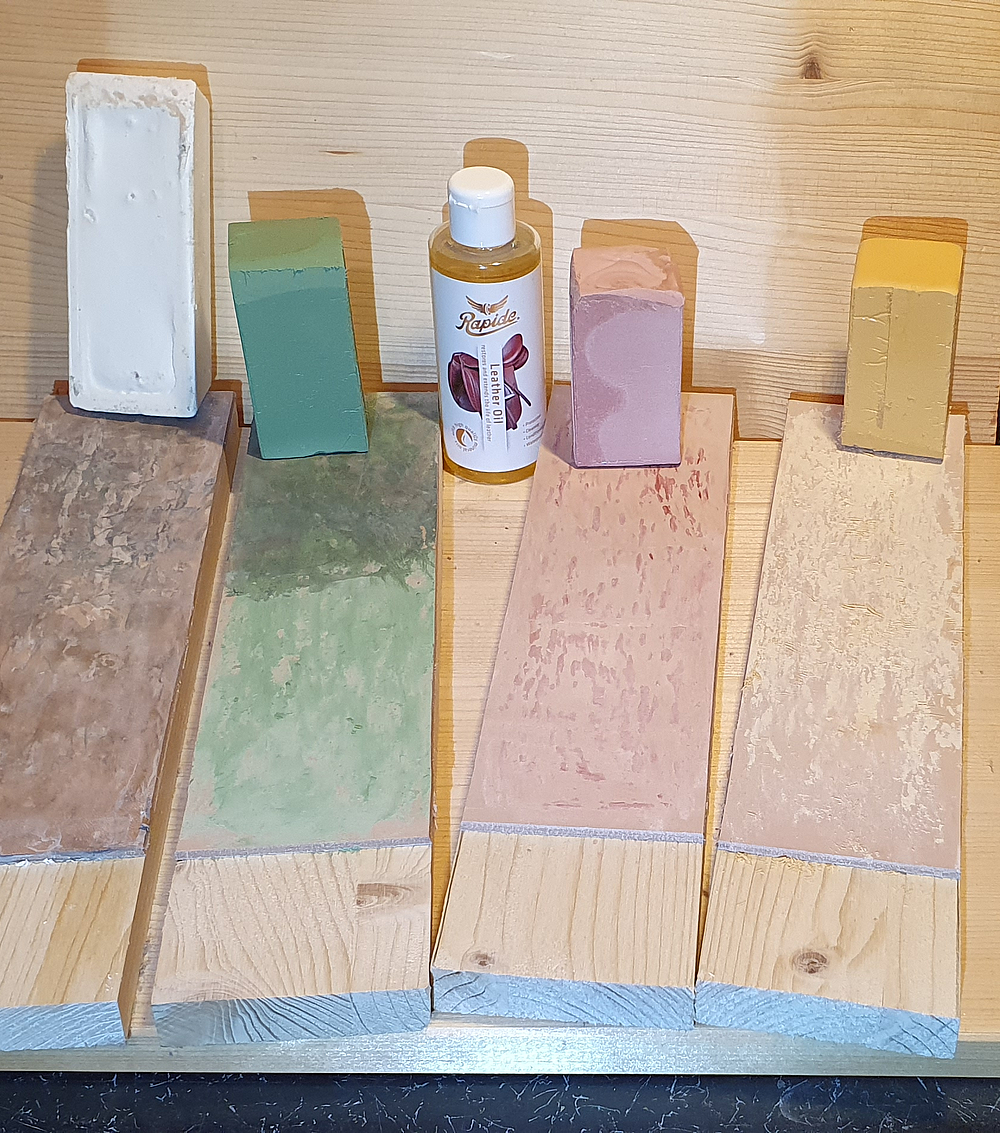

Fig: My homemade stropping leathers in various stages of completion

To achieve the final sharpness, or to remove the last burr, a stropping leather is usually used. The big advantage is that you can easily make your own stropping leather. The leather is cheap, and you can also get stropping paste cheaply. However, the handling is not quite simple.

The rough inside seems a bit rougher than the smooth outside. There is a leather stropping wheel on my grinder, rough side out. For the very last strop, the smooth outer leather without additional paste is also sometimes recommended.

Usually a stropping paste is applied to the leather. Unfortunately, the paste is usually not described in detail ("fine", "medium" and "coarse" often have to do). In addition, the wax used in this process is quite bad to handle. Since leather is a natural material, it is impossible to say exactly how deep the respective crystals are in the leather. So the aggressiveness of the strop is hard to gauge, especially on the rough side.

The wax used actually comes more from its use as a buffing wax, where it makes much more sense: when applied to the machine-driven fabric wheels, it heats up and softens a bit. So I would definitely prefer liquid or at least soft stropping emulsions.

A laudable exception is the company Jende Industries. Jende offers liquid strop pastes with precisely defined diamond grit sizes. However, I don't know how uniform they are then. But they also want to be payed well for this service. In addition, they also offer a synthetic leather substitute in the color that matches the respective grit. Another advantage: applying the paste is much easier than re-waxing with lumpy buffing wax.

Fig: Stropping block by Jende with polishing emulsion