Manual resharpening after machine sharpening

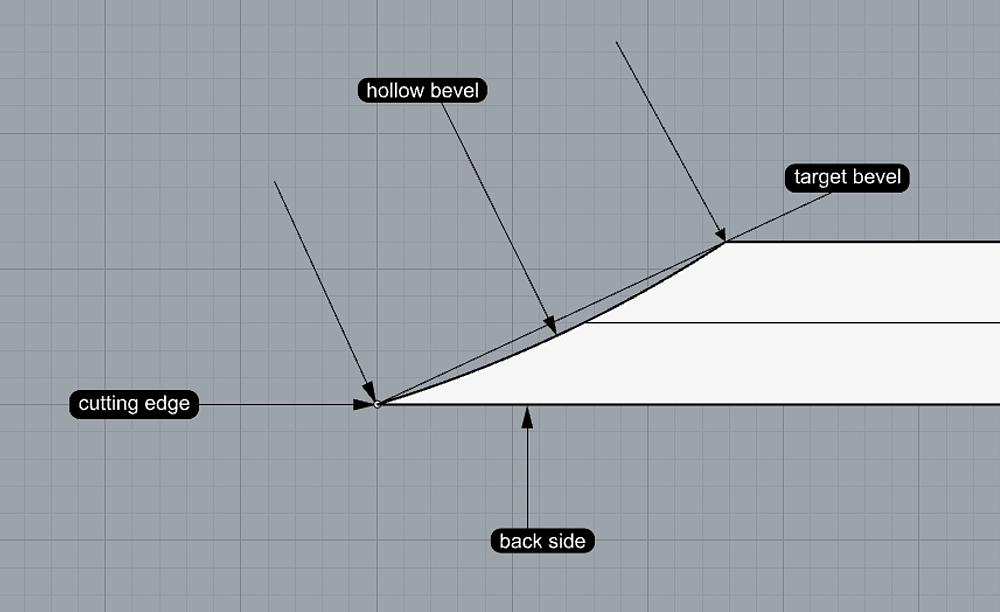

The idea is tempting: if you have a hollow grind, manual grinding becomes easier. You have to remove less material at the edges. But there's a problem, unfortunately. It makes little sense to grind the desired angle with the machine. As you can see here, this does little good. When using a round disc, quite a lot of metal remains, which then has to be ground away at length in order to get to the cutting edge at all. It would then be better to have ground a smaller angle by machine to match the manual bevel you are looking for. This angle is calculated from the target angle, the thickness of the iron and the diameter of the grinding wheel. See the calculator below!

You would then have 2 support points for the iron on the grindstone (red arrows). This would be a good fit for freehand grinding. If the machine angle were made a little smaller, the support point for the cutting edge would be retained and the other point would be omitted for the time being. You would then practically have a micro bevel. And only when you increase the micro bevel over time the other side would also come into the grindable range. This would be more appropriate for grinding with guidance.Addition: the smaller the grinding wheel, the deeper the hollow bevel, the longer the benefit.

Fig: Ideal angle for the hollow bevel (slightly smaller than the target angle)

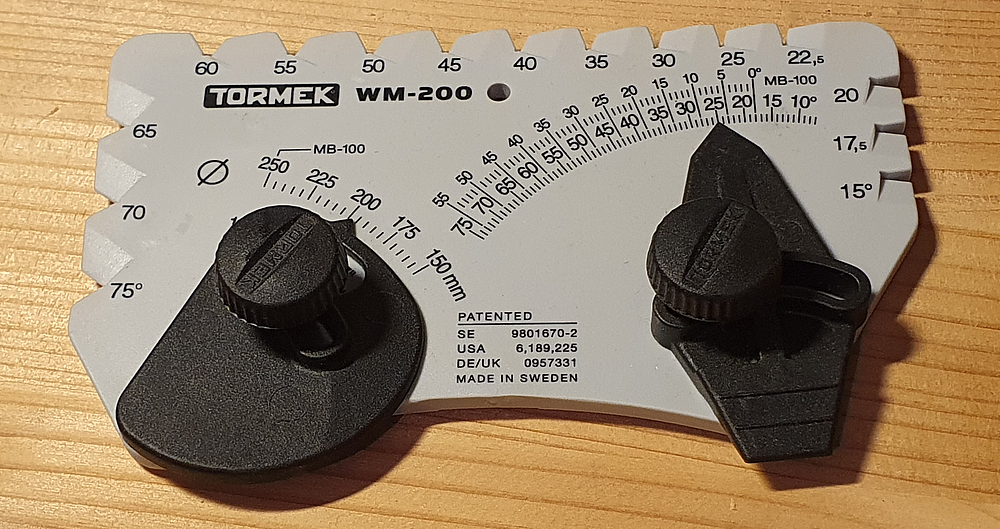

Prerequisite: Your machine offers a possibility to adjust the cutting angle. This is not easy, because you have to take into account the wear and tear on the disc.

Fig: Angle gauge for a possibly worn grinding wheel

Calculator to find the ideal angle for machine grinding (requires Javascript!)

Enter the requested values (please use decimal point, no comma). Please enter both lengths in the same unit. If either a number less than zero or "NaN" appears as the result, the problem cannot be solved. I suspect that then some input is not correct. As already mentioned above: in case of doubt, it is better to choose a slightly smaller angle!.