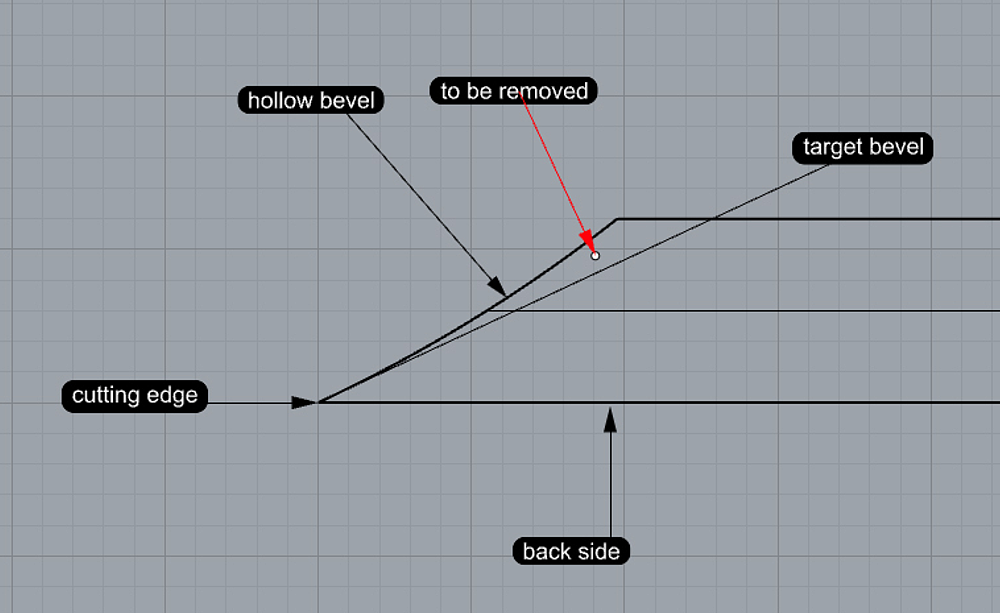

Grinding: the hollow bevel

A circular hollow bevel is created when you grind the bevel by machine with a grinding wheel (shown here somewhat exaggerated). The degree of hollowness is determined by the diameter of the disc. You can see that less material is removed here than if you had a straight bevel with the same cutting edge angle. The red arrow indicates the metal that protrudes compared to the straight bevel and would have to be removed (if you want to continue grinding with a flat stone). It becomes clear that there is quite a bit of effort involved in continuing to grind by hand an iron that has been ground in this manner.

You can find a possible solution here:Manual resharpening after machine sharpening.

Fig: The hollow bevel