What is sharpness anyway?

We speak of a sharp edge when two smooth surfaces meet without a rounding. So:

the two surfaces must be smooth. This means, in particular, that there must not be any clear grooves or nicks. And if one of the surfaces is eaten away by rust, you can hardly speak of sharpness because of that. Grinding marks from coarse stones also interfere there.

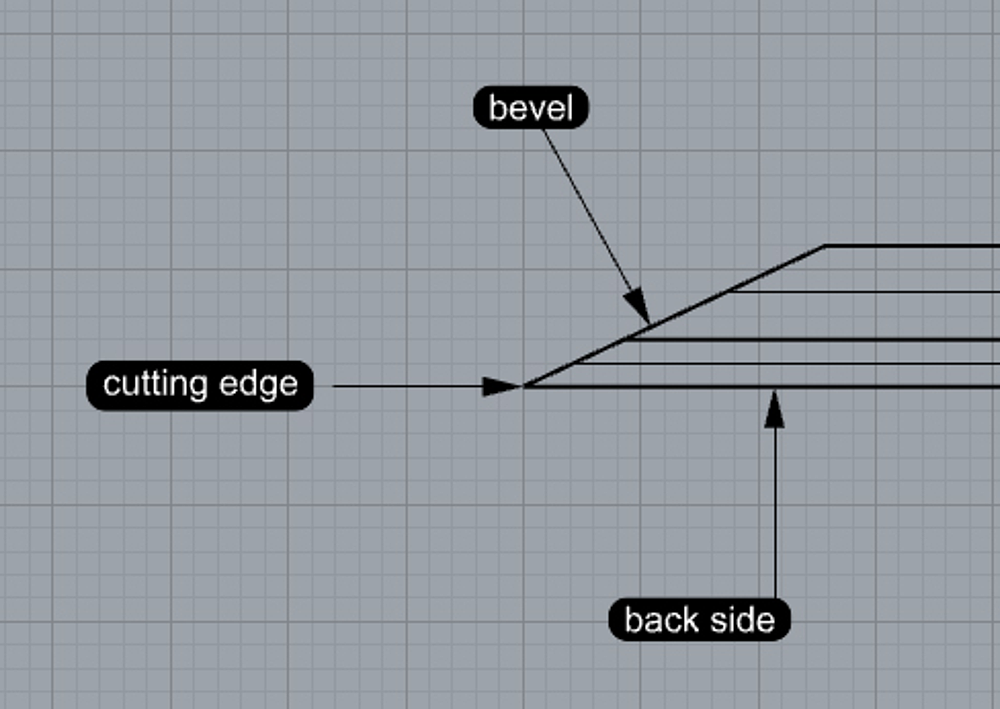

the surfaces must meet in an edge (called cutting edge), and not in a rounding (there must also be no burr). A rounding/burr must be removed as well as possible. From this you can immediately see that sharpness is relative depending on how much rounding/burr is left.

Whether chisel or plane iron: for the surfaces that determine the cutting edge, there are many possible variants. But what there is always:

the back side, which should be as flat as possible (unless we have a rear micro bevel)

the bevel: the inclined flat, which should also be smooth and flat (at least the last millimeter before the cutting edge).

Fig: Bevel and back side form a sharp cutting edge (here: straight bevel)

The picture is a bit misleading: The two surfaces must be smooth only in the immediate vicinity of the cutting edge. See the sections